Improved Borehole Technology for the Development of Geothermal Heating Systems

Boreholes with fiber optic measuring equipment makes it possible to evaluate thermal performance for boreholes of different lengths within the same borehole field.

Project description

The plus-energy houses are heated via a heat pump system with heat pumps and 12 drill holes totaling 3600m. The geothermal installation design has some unconventional features that make the installation very interesting for research purposes.

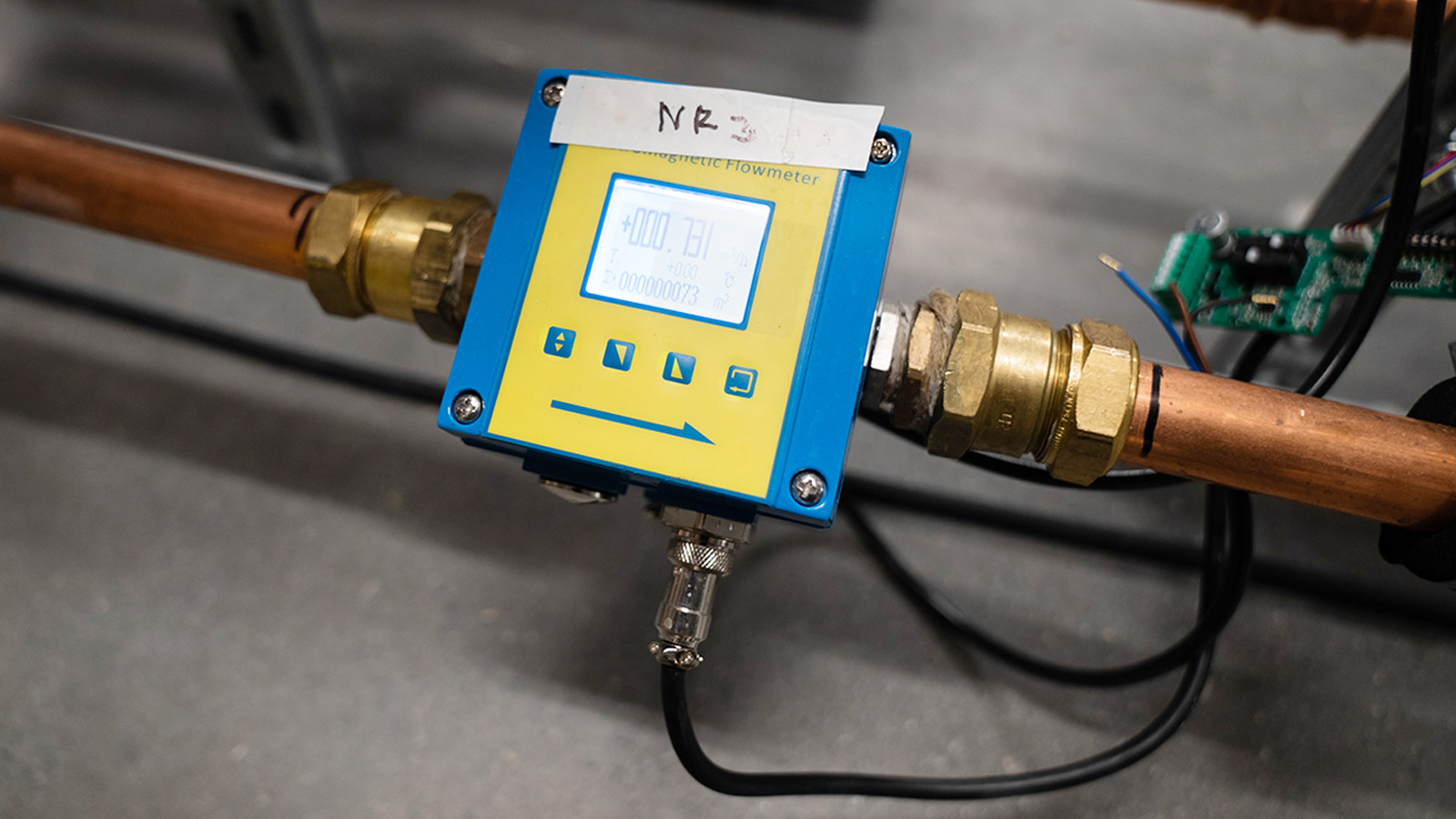

The boreholes range from 100 to 350 meters and have been equipped with measuring equipment to be able to evaluate thermal performance for boreholes of different lengths within the same borehole field. Both heat transfer between the loops as well as the temperature along the boreholes will be measured which results in heat transfer information in individual holes and throughout the borehole system. The temperature along the boreholes is measured using Distributed Temperature Detection (DTS), a fiber optic technology, and linear temperature sensors. Fiber cables have been installed in five boreholes and provide measurement values of the borehole temperature profile during operation.

In addition to the areas of monitoring and measurement, drilling research in the KTH Live-In-Lab will also include innovative heat exchangers and borehole testing methods. For this part of the project comes a dedicated "research drill hole" with a length of 100 meters and a coaxial design to be utilized. The concept behind this borehole is to provide borehole researchers with a highly flexible system to experiment with innovative ideas.

For this reason, the pipeline is designed so that the fluid circulating in the "research well" can be directed to a separate heat pump and operated with independent loads compared with the remaining part of the installation of the plus energy houses.

Implementation

The research heat pump system will be designed to accurately control heat supply and heat output to test the ground for a variety of load profiles with the aim of collecting valuable information to characterize short term thermal response for boreholes.

Final report

This report presents the final results of project Improved borehole technology for Geothermal Heat Pumps development financed by the Swedish Energy Agency. The project started in May 2017 and finished in June 2020. The project has been led by Dr. Alberto Lazzarotto and the work was carried out by Alberto Lazzarotto and Willem Mazzotti Pallard both from KTH – Royal Institute of Technology. Visiting students Adrien Vautrin from Insa Strasbourg and Thierry Richert from École Centrale de Lyon provided significant contribution to the project. Riccardo Sven Risuleo, postdoctoral researcher in machine learning at the University of Uppsala and KTH, also provided key contributions. The project benefited from in-kind contribution from Akademiska Hus, Asplan Viak, Avanti, Bengt Dahlgren, ClimaCheck, Einar Mattsson, Energi och Kylanalys, Geobatteri, HP Brunnsborrningar, Muovitech, Nowab, the Norwegian University of Science and Technology (NTNU), Palne Mogensen AB, Sindeq, Solifos, Stures Brunnsborrningar, Sweco, Thermia, Triopipe Geotherm, Tyréns, WellPerform, and Wessman Drilling Solution.

Read the whole report here: Improved Borehole Technology for Geothermal Heat Pumps Development (pdf 2.8 MB)